Solution Cases [case-009] Energy Saving of Vertical Furnace for Low Temperature Range

- Polymide curing

- VF-3000(B)

Improvement of vertical furnace to energy saving by optimizing thermal insulation design

| Support Process | Polymide curing |

|---|---|

| Model Introduced | VF-3000 Low-Cost Mini Batch Vertical Furnace |

Problem

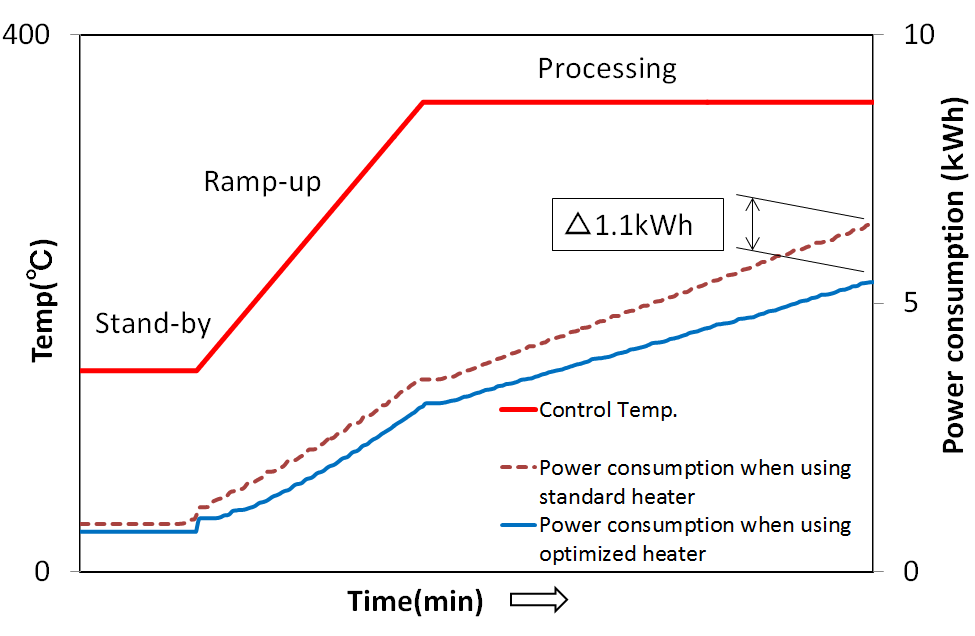

The vertical type furnace equipped with our Light Gauge Over-bend heater (Moldatherm) can perform a wide range of high quality heat treatment from low temperature (200 deg – C) to high temperature (1150 deg – C). As energy saving efforts, we have focused on processing furnaces in the high-temperature to mid-temperature range (600 to 1100 deg-C) so far, but when using high temperature to medium temperature processing furnaces as production lines dedicated to low temperature range, There was a problem that the amount of electric power for heating the heat insulating material became more than necessary.

Solution

- Developed Light Gauge Over-bend heater dedicated for low temperature range.

- Optimized the heat capacity and heat dissipation balance of the insulation in the operating temperature range.

- Produced a heater prototype and verified its performance.

Results

- Reduced power consumption : 1.1kWh/run *

- Reduce CO2 emissions : 742kg/year *

(Remarks* :Condition of calculation example)

Application :Polymide curing

Processing wafer :6inch × 75wafers

Annual number of times of processing :6run/day × 300days/year