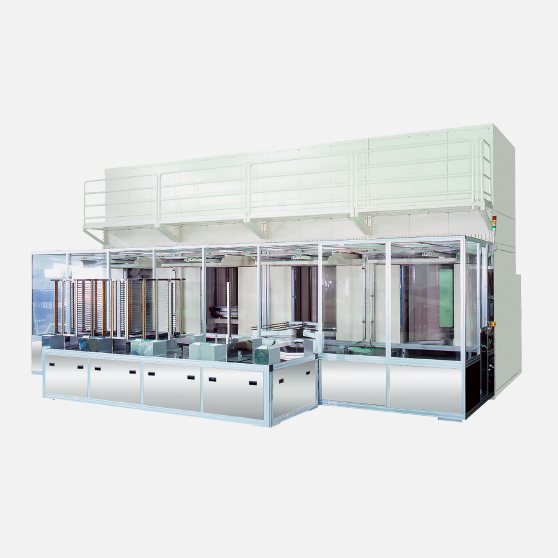

Large Bore Vertical Furnace

Overview

This large-bore vertical furnace employs strict temperature characteristic control, atmosphere control and particle control, expertise for semiconductor manufacturing, for FPD. Quartz boats are used to create a low-particle, metal-free environment to enable vacuum heat treatment at 10 ppm or lower O2 concentration. This furnace is suitable for touch panel and other material contact annealing, post-baking and activation annealing. In addition, for advanced semiconductor packaging such as chiplet and 2.xD/3D, this furnace is available for various heat treatment of RDL (Redistribution Layer) based on glass substrate, glass interposer, etc.

Specifications

| Model | VFS-4000 |

|---|---|

| Outer dimension (mm) | W2000 × D2000 × H4350 (furnace body) |

| Heater | Light Gauge Over-bend heater |

| Operation temperature | 200~600°C |

| Substrate size (mm) | LCD/OLED : 730×920 (other sizes on request) Advanced Semiconductor Packaging : 300×300, 510×515, 600×600 |

| Batch size | 24 wafers *For LCD/OLED : 730×920mm It may vary depending on wafer thickness and warpage. |

| Chamber material | High-grade quarts |

| Controller | Model VSC1000 |

| Option | Forced-cooling system, HOST communication (SECS/GEM) |

| Applications | LCD/OLED : Contact Annealing, Post-bake, Activated annealing Advanced Semiconductor Packaging : Curing of RDL and PCB, Reflow after solder bumping |

Applications

Customize

Related Solution Cases

-

See Solution Cases

[case-006] Improving Yield for FPD Applications

Achieving heat treatment at the cleanliness level of semiconductor fabrication equipment

- Metal contact annealing (for FPD)

- Frit firing (for FPD)

- Dehydrogenation (for FPD)

- Activation (for FPD)

- Curing (for FPD)

- VFS-4000

-

See Solution Cases

[case-016] Low cost large bore vertical furnace

Cost reduction of large bore vertical furnace by optimizing required functions

- Curing (for FPD)

- VFS-4000