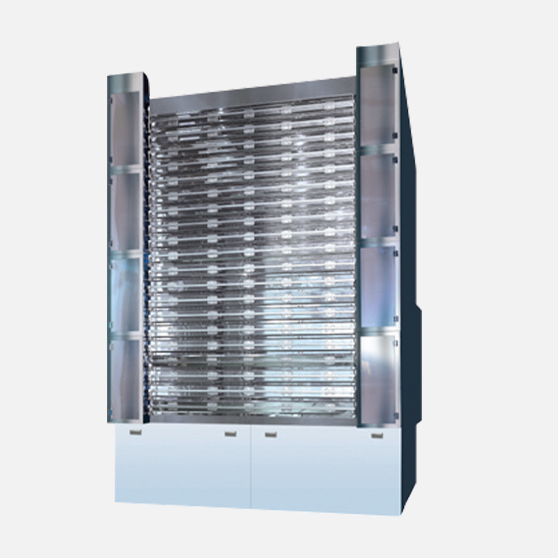

IR Furnace, Single Substrate Transfer Type

Overview

High-level clean factor

The clean structure that does not generate dust, combined with precision oven atmosphere control (patent acquired), deliver a high level of clean performance.

These ovens are also capable of processing array substrates that require a strict clean environment.

High heating efficiency

A far-infrared (IR) heating system with superior heating efficiency is used, and is capable of high-efficiency processing of all film thicknesses.

It is ideal for processing of thick films such as alignment layers and passivation films.

Excellent temperature uniformity

The adopted IR panel heaters deliver excellent temperature uniformity. They are capable of uniform heating even of large-size substrates such as 10th generation.

Capable of atmosphere control

Nitrogen gas can be injected into the oven to perform heat treatment at low oxygen concentrations.

Specifications

| Model | CCBS-IR |

|---|---|

| Substrate size (mm) | 300 (W) × 400 (L) to 3000 (W) × 3200 (L) |

| Operating temperature range | RT to 250°C |

| Temperature accuracy | ±3°C |

| Clean factor | Class 10 (0.3μm) |

| Applications | IGZO production, LTPS production, baking of alignment layers and array substrates, various array process annealing, baking of passivation films, seal main curing and pre-curing, various heat treatments for organic EL |