JTEKT Thermo Systems Vertical Furnaces

Vertical furnaces are used for processing wafers during semiconductor device manufacturing—including for film formation, annealing, and resin film hardening. These batch processing furnaces feature a vertically arranged quartz tube that heats objects placed around the tube for processing. Wafers are loaded onto quartz storage shelves called boats, which are loaded/unloaded from the bottom of the process tubes. With minimal particle generation, the furnaces provide excellent temperature distribution and atmosphere control. In addition, automatic wafer and boat transfer makes it possible to further improve productivity.

Conventional horizontal furnaces are prone to non-uniform film thicknesses within a batch and on wafer surfaces as well as particle and natural oxide film generation, and the equipment itself requires more area due to the increased wafer diameters. Vertical furnaces, however, are not limited by such problems, which factors into their mainstream popularity.

JTEKT Thermo Systems entered the semiconductor manufacturing equipment market in 1970 with the release of a horizontal heat treatment system manufactured under the Tempress Japan brand.

The Company has since provided a wide range of heat treatment technologies that have played a role in the growth and development of the semiconductor industry both in Japan and around the world.

Our focus on the niche markets we excel in and makes every effort to develop the new technologies and equipment those markets demand.

JTEKT Thermo Systems’ ability to propose various equipment—from small-volume production equipment for research and development and for state-of-the-art devices, to full-scale production equipment—can be utilized to provide satisfactory results that meet customer requirements.

Vertical Furnace LINEUP

| Products | |||||||

|---|---|---|---|---|---|---|---|

| Outer dimension | W1250 × D3200 × H3450 mm | W1250 × D2000 × H2850 mm | W900 × D2300 × H3300 mm | W1000 × D1950 × H3300 mm | W1200 × D1450 × H2610 mm | W1500 × D1000 × H2130 mm | Varies by specification |

| Flat zone length | 1040 mm | 500 mm | 960 mm | 360 to 960 mm | to 360 mm | to 250 mm | Varies by specification |

| Wafer size | 300 mm | 300 mm | 6 to 8 inch | 4 to 8 inch | 4 to 8 inch | to 8 inch | Varies by specification |

| Batch size | 100 wafers | 50 wafers | 150 wafers | Max. 150 wafers | Max. 75 wafers(50 wafers at 8 inch) | to 25 wafers | 20 to 25 wafers |

| Number of Stock | 16 FOUP | - | 20 Casette | 4 to 8 Casette | 4 to 8 Casette | - | Varies by specification |

| Robot Finger | 5 wafers + single wafer | 5 wafers + single wafer | 5 wafers + single wafer | 5 wafers + single wafer | Single wafer | - | Single wafer |

| Apprications | Semiconductor, SiC Power Semiconductor, MEMS, VCSEL, PV (Photovoltaic) | FPD | |||||

Related Solution Case

-

See Solution Cases

Establishment of the VCSEL Process

Significant yield improvement was achieved with a special VCSEL-process dedicated furnace.

- Thermal oxideation

- VF-3000(B)

-

See Solution Cases

Improving Yield for FPD Applications

Achieving heat treatment at the cleanliness level of semiconductor fabrication equipment

- Metal contact annealing (for FPD)

- Frit firing (for FPD)

- Dehydrogenation (for FPD)

- Activation (for FPD)

- Curing (for FPD)

- VFS-4000

-

See Solution Cases

Increasing Yield by Reducing Contaminants Within the Furnace

Reducing sediment with an automatic cleaning mechanism inside the furnace

- Curing (for FPD)

- VF-5300(B)

-

See Solution Cases

Improved Experimental and Development Accuracy

Improving experimental and development accuracy with a high-performance small-scale vertical furnace for experiments

- Annealing

- VF-1000(H)

Vertical Furnace Optimized Design

Flexible equipment layout

It is possible to move the gas box, etc. attached to the furnace to the rear side or under the floor and not just to the front or in the back. We can work around the restrictions of the equipment area and improve the maintainability of the equipment.

Vertical Furnace example

- Support for gas box layout changes

- Support for treatment using a liquid source at atmospheric pressure

- Support for selenization (Se) / sulfurization (S) treatment

- Vacuum support for large-bore furnaces (G4 size or larger)

- Carbon nanotube growth equipment

- Support for thin wafers (80μm or more)

- Fan-out wafer-enabled equipment

- Substrate support for large, FPD polyimide-cured panels

- Support for wet vacuum processing

- Support for dry vacuum (oxygen partial pressure control) processing

- Support for in-situ cleaning using ClF3

- Support for processing bulk transports of quartz cassettes

[Summary] The quartz cassette with wafers is transferred as it is, stacked, and subjected to heat treatment in that state. - Support for flat poly-Si (with no temperature inclination)

* Support varies depending on the model.

Demonstration and test areas

Comprehensive manufacturer of heat treatment equipment, which solves heat treatment problems from different fields beyond the boundaries of fields and areas

From equipment for research and development to production facilities, by assembling technicians in major business areas for vitalization of new products and technology development, and by installing our demonstration equipment for experiments and evaluations, JTEKT Thermo Systems is not only developing processes of its own but also providing the system that can be used for customers’ pre-tests and for performance evaluation.

Semiconductor manufacturing system area Inside the experimental laboratory, air cleanliness of Class 10 or higher must be ensured.

FAQ

-

- QWhere can I purchase the product?

- A

After finalizing the specifications with the customer, we custom-build their order for them. We do not sell products wholesale or by mail order. For more information, please contact us.

Please click here for inquiries. Company Offices

-

- QPlease tell me the product’s price.

- A

Equipment specifications and price vary depending on the product. Please contact us.

Please click here for inquiries. Product Information

-

- QWhat kinds of heat treatment equipment do you handle?

- A

We handle heat treatment equipment that can heat or add reactive gas to materials such as Si wafers, metal, rubber, glass, plastic, and fine ceramics during the film formation process to change the characteristics of those materials.

Product Information

-

- QCan you produce products not listed on the products page?

- A

Please send us your request. We will propose optimal equipment specifications. For more information, please contact us.

Please click here for inquiries. Technologies / Solutions

-

- QCan I verify the process in advance?

- A

We do not lend out any products but we can perform a demonstration to verify a product’s performance. If you have any demonstration requests, please contact us.

Please click here for inquiries. Demonstration Facilities

-

- QI am worried about whether I can operate and maintain the newly purchased equipment.

- A

We provide training before delivery of purchased equipment so the customer and his/her staff members can use the equipment without worry. If you have any questions after delivery, we also provide support by telephone or email. Please contact our sales representative.

Support

About JTEKT Thermo Systems

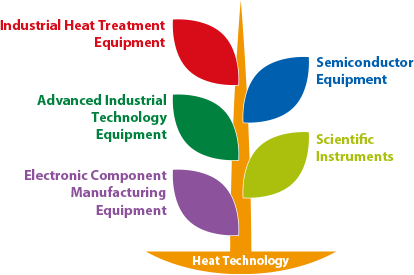

The metallic components, ceramics, etc. of formed and fabricated materials that form the foundation of the industry; the semiconductors and electronic components that support the latest technologies; the displays that enrich people's lives and next-generation batteries that control global environment pollution; and experimental developments to create all of these industries—it is not an overstatement to say that the heat treatment equipment created by JTEKT Thermo Systems is involved in all of the industries in our lives. With the unique technology created by the "Technology Tree" that fused the five pieces of "Technology Leaves" that were cultivated with a history spanning half a century, we continue to contribute to every field in the world.

International Offices

HEAD OFFICE

1. JAPAN (Tenri)

JTEKT Thermo Systems Corporation

-

KOYO THERMO SYSTEMS KOREA CO., LTD.

-

3. CHINA (Shanghai)

KOYO THERMO SYSTEMS TRADING (SHANGHAI) CO.,LTD.

-

4. TAIWAN (Taipei)

KOYO THERMO SYSTEMS ASIA CO., LTD.

-

5. TAIWAN (Taichung)

KOYO THERMO SYSTEMS ASIA TECHNICAL SERVICE OFFICE IN TAICHUNG

-

6. THAILAND (Bangkok)

JTEKT MACHINERY (THAILAND) CO., LTD.

-

SANDVIK THERMAL PROCESS, INC.

-

CRYSTEC TECHNOLOGY TRADING GmbH