AllFit Heat treatment equipment with superheated steam

Effective in reducing processing time and improving processing quality when degreasing electrostatic chucks, MLCCs, and ceramic parts!

To provide heat treatment technology that meets the needs of all customers, JTEKT Thermo Systems has developed a manufacturing equipment series that utilizes a superheated steam atmosphere.

These heat treatment devices are available as batch or continuous types.

JTEKT Thermo Systems also offers a lineup of products for experimental development R&D, small-volume production, and mass production.

Main features and application examples of superheated steam

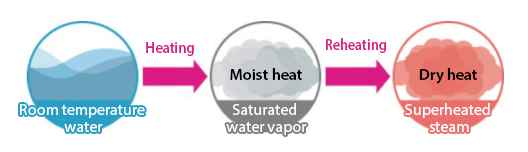

What is superheated steam?

H2O dry gas (low oxygen state) generated by heating saturated steam evaporated at 100°C to an even higher temperature under normal pressure.

Main features

Improves processing quality and reduces processing time

- Decomposes organic matter through hydrolysis*.

*A reaction in which organic compounds are decomposed by reacting with water - Has higher specific heat than heated air and higher drying capability (at a certain temperature or higher).

Can also get radiation effects. - “100% H2O” dry gas (low oxygen condition)

- Extremely high heat transfer due to condensation heat

Expected to shorten the heat processing time and improve processing quality

The superheated steam market

Superheated steam temperature

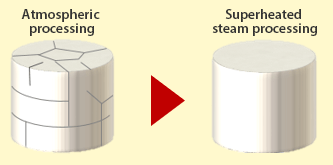

For example, when de-binding ceramic molded products and electronic components (MLCCs, electrostatic chucks, ferrite cores, etc.)

By hydrolysis,

① Exothermic reactions and gas generation are reduced, reducing impacts to and cracking on molded objects.

② Reduces binder carbide residue compared to nitrogen gas

Application examples

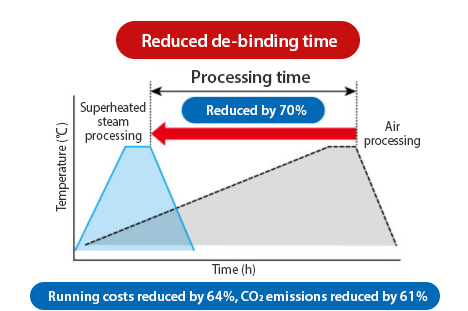

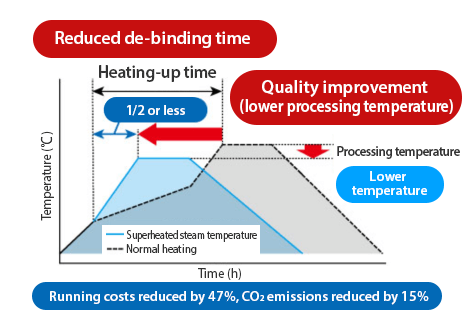

*The following figures are reference values compared under specific conditions. The degree of effectiveness varies depending on the material being processed.

-

De-binding of ceramic molded products

-

De-binding of electronic components

Other application examples

- Surface treatment of metal parts (homo treatment, bluing)

- Burning off resin

- Various cleaning applications

- Carbon fiber recovery from CFRP

The AllFit Lineup

Batch-type

-

Inert Gas Oven with Superheated Steam

- Compact

- Supports everything from experimentation and development to mass production

- We have a rich track record of delivering de-binding furnaces.

-

Atmospheric Box Furnace with Superheated Steam

- Compact

- Supports everything from experimentation and development to mass production

Continuous-type

-

Compact Conveyor Furnace with Superheated Steam

- Possible to introduce different gases into the system (atmosphere separation)

- Compatible with various temperature patterns

-

Mesh Belt Type Continuous Furnace with Superheated Steam

- Possible to introduce different gases into the system (atmosphere separation)

- Compatible with various temperature patterns

- Can be customized according to production volume

Ancillary equipment

Exhaust Gas Treatment Equipment

-

- Decomposes binder in exhaust gas

- Removal of bad odors that cannot be removed with catalysts (improvement of work environment)

- The optional heat exchanger reduces power consumption by 25%.

Optional equipment

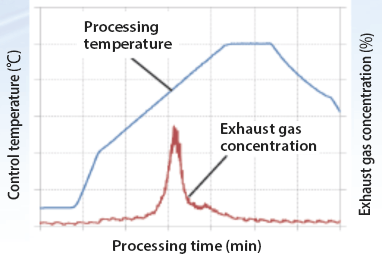

Exhaust gas concentration monitoring system

Visualizes de-binding by measuring exhaust gas concentration

- Effective for determining the optimal de-binding treatment profile

- Visualizes the decomposition behavior of the binder in a superheated steam (also compatible with atmospheres such as air and N2).

- Can be retrofitted to existing furnaces

Introduction of special cases

-

Inert Gas Oven with Takt Feed

- Outstanding productivity through continuous processing

Please contact us for product details.

About superheated steam demonstrations

We have a wide variety of demonstration equipment, from small to large batch furnaces, continuous furnaces, etc., and the customer can perform demonstrations in our factory tailored to the customer’s processing method, production form, and processing amount. Please contact our sales representative for details.

Click here for inquiries and requests for demos and trial firings